What My Workshop Taught Me About HDD Tools

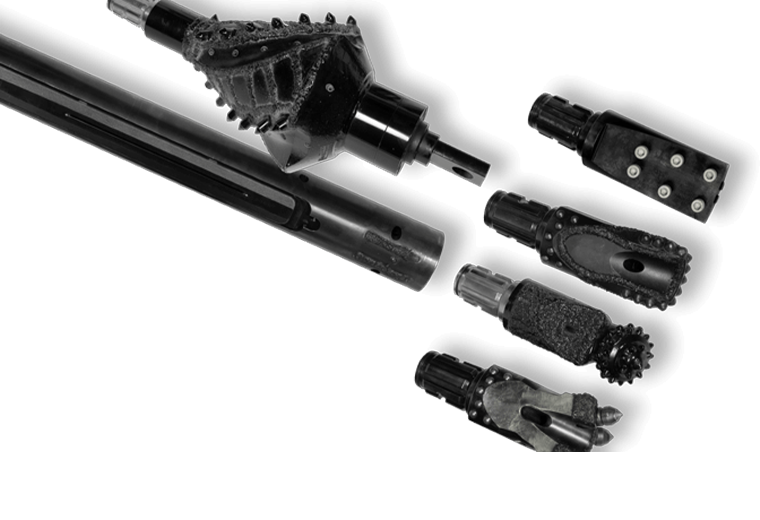

Hey folks, grab a cup of coffee. Let’s chat. I’ve been thinking a lot about the corner of our workshop where we keep all the HDD tool samples. It’s my favorite spot. Why? Because magic happens there.

It’s where spec sheets come to life and where frustrations get solved, not with a sales pitch, but with a “hey, look at this.”

That One Worn-Out Bit That Changed Everything

I’ve been here five years, and I still learn something new every week from these samples. The biggest lesson came early on. A client, let’s call him Mike, stormed in holding a drill bit like it had personally offended him. “It just quit on me!” he said.

We stood right by that shelf, comparing his busted bit to a new one. The wear pattern was a perfect map of his job site’s hidden troubles—a layer of abrasive sandstone he hadn’t expected. We weren’t just looking at a tool; we were doing archaeology on a failed bore.

That was my lightbulb moment. These samples aren’t just products; they are the best teachers. They show the why behind the what. Now, when I see a cracked wear pad or a polished thread, I see a story waiting to be told.

Why Your Fingertips Are Smarter Than a Catalog

You know that feeling when you heft a tool and it just feels right? The balanced weight of a short-radius rod, the satisfyingly smooth turn of a premium coupling—you can’t get that from a PDF.

I can write “high-grade steel” all day, but when you hold our sample rod next to a cheaper one and feel the difference in your hands? That’s conviction.

I’ve seen seasoned superintendents stand silently for five minutes, just turning two subs over in their hands, comparing the machining. They’re not listening to me; they’re listening to the tool. And the tool never lies. That’s why I insist: come touch the stuff.

Get a little grease on your hands. That dent on the reamer body? That’s from me being clumsy. That perfectly clean thread? That’s what keeps your connection solid at 200 feet. The evidence is all right here.

The “Coffee Break” Demo That Solved a Month-Long Headache

My best meetings often feel like casual shop talk. Like when Sarah, who runs a midsize crew, popped in looking tired. They were battling inconsistent steering in a mixed soil job. We grabbed fresh coffees and wandered over to the samples.

Instead of talking specs, we started playing with stabilizer configurations on a sample drill head, right there on the bench. “What if your ground is doing this?” I asked, mimicking wobble with my hands. We swapped parts around like LEGO, sketching in the dust on the table.

That 20-minute, no-pressure brainstorm—centered on real, tangible parts—gave her a new setup to try. She texted me a week later: “That weird combo we built? Works like a charm.” That’s the goal. It’s not a transaction; it’s problem-solving, with physical pieces of the puzzle right in front of us.

Your Invitation to Geek Out

So here’s the thing: I’m a tool nerd. I get genuinely excited about thread profiles and carbide placement. And I bet you have insights and headaches that would fascinate me.

That shelf is our common ground. Whether you’re a potential client trying to picture how our tools fit your rig, or a longtime partner facing a new challenge, the invitation is the same.

Swing by. Let’s pull a few samples off the shelf, point at the features that matter, and trade stories from the field. No hard sell, just real talk about real tools.

Keep boring smart

By Frank

HDD Engineering Sales

RICHDRILL EQUIPMENT CO.,LTD

Share :