Hey there! Pullback day—it’s like the season finale of an HDD project. The planning, the pilot hole, it all leads to this moment. I remember years ago, standing by a rig in the drizzling rain, watching a crew struggle during a pullback.

My boss turned to me and said, “They’re fighting their tools.” That stuck with me. It’s not just having the tools; it’s knowing how they become a team underground. Let’s chat about who’s who in that lineup.

The Drill Pipe: The Quiet Workhorse

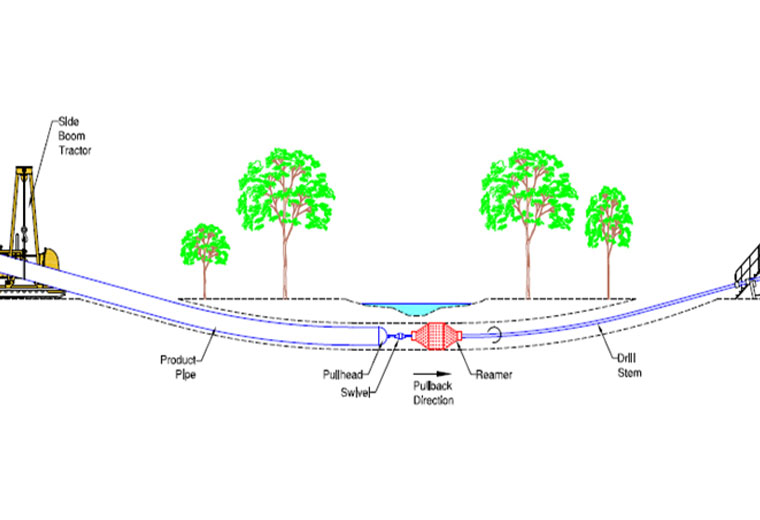

Let’s start with the obvious: your drill pipe is already in the hole. During pullback, its job changes. It’s no longer just drilling; it’s the vital link transmitting all that torque and pull force from the rig to the front lines.

Think of it as the train tracks your whole operation runs on. I’ve seen guys get so focused on fancy reamers that they neglect their pipe thread inspection. Big mistake. A worn shoulder or compromised thread here is like starting a cross-country road trip with a shaky wheel—you might not feel it at first, but the failure won’t be subtle.

The Reamer: It’s All About the Match

Ah, the reamer. This is where personalities come out. I love geeking out on reamers. There are barrel reamers, fly cutters, hole openers with carbide… the list goes on.

My “aha” moment? On a job in stubborn clay, the crew used a super-aggressive, big-tooth reamer because it was “the biggest we had.” The result? It basically balled up the clay into a giant, sticky plug that stalled everything.

We swapped it out for a more flow-through designed reamer, and it was like the hole started breathing again. The lesson? It’s not about size or toughness alone. It’s about choosing the one that will manage the cuttings and slurry for your specific soil. A good reamer prepares a clean, stable highway for your product pipe, not just a bigger hole.

The Swivel: The Unsung Hero

If I had a dollar for every time I’ve said, “Check your swivel!”… This humble piece sits between the reamer and your product pipe. Its only job is to let the reamer spin wildly while your product pipe doesn’t. Seems simple, right?

I once watched a crew reuse a swivel way past its service life because “it still turns.” Mid-pullback, it seized. The torque transferred straight into the brand-new polyethylene pipe, twisting it like a licorice stick. The groans from the crew were louder than the rig. That tiny cost-saving turned into a massive, muddy recovery operation. The swivel is your insurance policy. Never, ever skip on it.

The Pull Head & Connection: The Handshake

How you attach your product pipe is everything. You’ve got pull heads that get cemented into the pipe end, or gripping systems that clamp on. This is the handshake between your drilling string and your precious cargo.

My personal rule? This connection should be the strongest link in your whole chain. I’m a bit paranoid here, probably because early in my career, I saw a poorly installed pull head pop off halfway. The pipe sank to the bottom of the enlarged hole, and let’s just say the diving and recovery operation wasn’t in the original bid. Take your time here. Clean the pipe, follow the specs, and double-check it. This isn’t a place for shortcuts.

The Supporting Cast: Don’t Forget the Backups

The Pull Head & Connection: The Handshake

Pullback isn’t a one-tool show. A few other backstage heroes:

- Safety Clamps: Always, always have a solid safety clamp on the pipe right at the rig entrance. It’s your last-chance brake if something slips.

- Rollers & Cradles: These keep your product pipe from getting scraped and damaged as it feeds into the hole. Dragging it on the dirt? Just don’t.

- Your Fluid System: Yes, even during pullback! It’s not just for drilling. Good slurry flow keeps the hole stabilized, lubricates the pipe for less friction, and carries away any remaining cuttings. If your fluid looks like thick mud, you’re asking for trouble.

So, that’s the crew: the steady drill pipe, the matched reamer, the faithful swivel, the trustworthy connection, and the vigilant support team. It’s a system, not a list. When it syncs up, watching that product pipe slide smoothly into the earth is one of the most satisfying things in our line of work.

What about you? Ever had a tool surprise you—for better or worse—during a pullback? Shoot me a message and tell me your story. I’m always collecting tales from the field.

Keep drilling smart,

By Frank

HDD Engineering Sales

RICHDRILL EQUIPMENT CO.,LTD

Share :