Hey friends, grab a coffee and let’s chat about something that’s easy to overlook in our world of big machines and long pulls: the starter rod. You know, that first piece of steel you thread onto the back of your drill head. I used to think of it as just… another rod. Until I learned the hard way how much it actually runs the show.

My “Duh!” Moment on Site

A few summers back, I was visiting a crew working on a utility bore under a quiet neighborhood street. Good guys, solid rig, but they were fighting the ground from the get-go.

The driller was making constant steering corrections, the fluid returns were messy, and everyone looked tense. They’d already chewed through a couple of back reamers earlier that week. We were all scratching our heads.

On a whim, the foreman swapped out their starter rod—a slightly bent, older unit they’d been reusing—for a new, spec-matched one from the truck. The next pilot bore felt… calm. Not perfect, but suddenly predictable. The machine noise even sounded smoother.

It was like the drill string finally remembered how to walk straight. That’s when it hit me: we’d been blaming the ground, the head, the alignment… but the problem started at the very first connection. It was a humbling (and slightly embarrassing) lesson for someone who’s supposed to know this stuff.

It’s Not Just a Rod, It’s the Translator

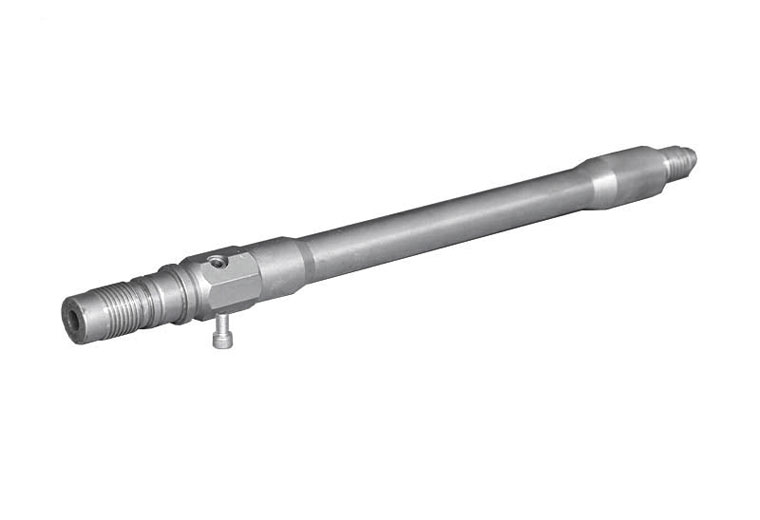

Think about it. Your drill head is out there, spinning and cutting, trying to read the soil. All that feedback—the vibration, the torque, the resistance—gets sent back through the string. The starter rod is the first point of contact. It’s the translator between your head and the rest of your rods.

If it’s tired, slightly out of spec, or just not the right design for the job, the translation gets garbled. It’s like talking on a bad phone connection—you miss nuances, you misinterpret signals, and everything gets harder. A proper starter rod gives your drill head a clear voice and helps the whole string understand what’s happening up front.

What Makes a Good “First Date” for Your Drill Head?

I’m not going to get super technical here, but let’s break down the basics in plain talk:

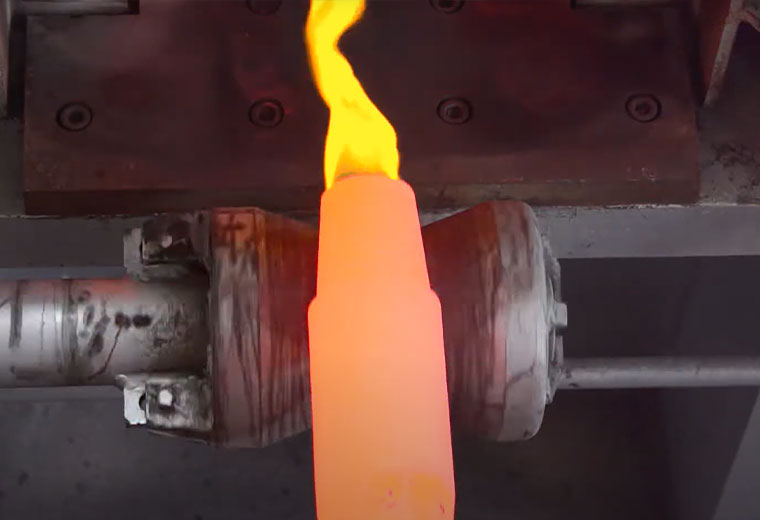

- The Stiffness Factor: It needs to be rigid enough to push straight, but still have some “feel.” Too whippy, and you lose steering precision right where you need it most.

- Threads That Can Take a Beating: Those first few threads see insane stress. A clean, sharp, and perfectly formed thread isn’t a luxury—it’s your first line of defense against wear that travels down the string.

- Length & Weight: It’s often shorter and heavier. Why? To add stability right behind the head, helping it act like a steady guide rather than a flexible follower.

- The “Don’t Reuse Me Forever” Rule: This is my personal soapbox. Starter rods work the hardest. Using one that’s seen 200 bores for a critical job is like putting bald tires on a race car. It might hold, but you’re asking for trouble.

A Small Choice That Echoes Down the Hole

Choosing the right starter rod isn’t about buying the most expensive one. It’s about being intentional. It’s acknowledging that the start of the bore sets the tone for everything that follows—the wear on your head, the stress on your rods, the smoothness of your pullback, even your operator’s stress level.

It’s the cheapest insurance policy you can get on a bore. Ignoring it is like skipping the foundation inspection because you’re excited to build the roof.

Your Quick Win for Next Week

So here’s my challenge to you: Next time you’re on the rig or planning a job, take two minutes. Look at that first rod. Give it a clean. Check the threads. Ask yourself: “Is this the best ambassador I can send out with my drill head?”

Sometimes, the biggest gains come from paying attention to the smallest, most humble piece of the puzzle. Drill smart, and take care of where it all begins.

Keep drilling smart,

By Frank

HDD Engineering Sales

RICHDRILL EQUIPMENT CO.,LTD

Share :