Hey there! Let’s Talk About HDD and Weather Woes

So, picture this: It’s last July, and I’m standing on a jobsite in Texas at 2 PM. The sun feels like a giant heat lamp, and my water bottle is basically hot tea. The crew was trying to hit a deadline, but the rig was moving slower than my motivation on a Monday morning. The mud was thinning out faster than we could mix it.

That’s when it really hit me (aside from the heat): Temperature isn’t just about comfort—it’s a silent partner on every HDD job.

We always plan for soil conditions, torque, and pullback force. But how often do we stop and think, “What’s the weather doing to my whole system today?”

Let me share a few “aha” moments I’ve had over the years—some learned the hard way.

In the Scorching Heat…

Ever tried to keep your drilling mud happy in 100°F+ weather? It’s like trying to keep a slushy from melting. The fluid evaporates faster, properties change, and it can lose its viscosity and carrying capacity when you need it most. I once saw a crew adding water constantly, just throwing the whole chemistry off.

Lesson? Monitor your fluid more often when it’s hot. And for heaven’s sake, keep your team hydrated and shaded. Heat exhaustion is no joke—safety always comes before schedule.

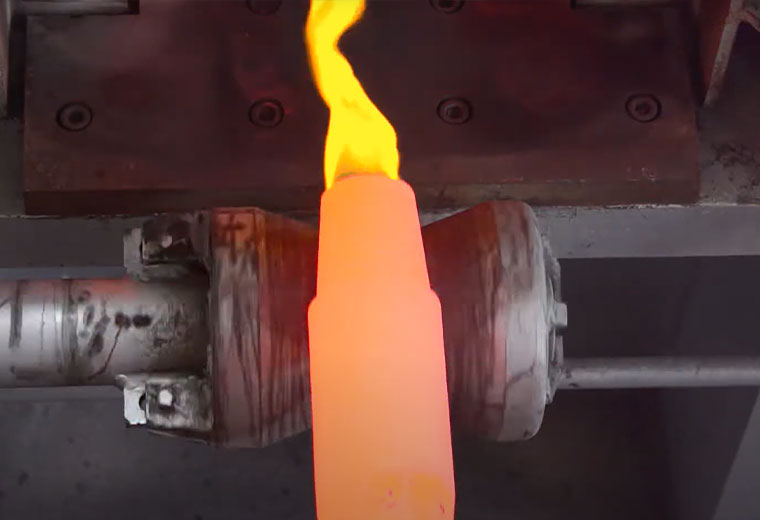

Oh, and your equipment feels it too. Hydraulic systems can overheat, seals get stressed. We tend to push harder in summer, but sometimes, slowing down just a little keeps things running smoother (and longer).

When the Cold Creeps In…

Now, let’s flip to a winter job in Ohio a few years back. Frost line deeper than expected, ground stiff as concrete. The drill pipe felt… brittle. Not literally, but you could tell everything was tighter, less forgiving. Cold makes steel tougher but also more susceptible to shock loads. Your nice, fluid bends can become more abrupt.

And mud? Forget it. If it’s freezing, you’re basically pumping sludge. Fluid lines can ice up, and storage tanks turn into giant popsicles. I learned to always ask about temperature ratings for additives and to allow extra time for morning warm-ups—for both machines and people. Nobody thinks clearly with numb fingers.

My Simple “Weather Check” Habit

Now, before any project chat, I casually ask: “What’s the usual temp swing there this time of year?” It’s not small talk. It tells me if we should discuss insulated mud systems, different grease types, or even just planning more breaks.

It’s not about selling you something “special.” It’s about making sure what you already use performs like it should. The right drill pipe, properly cared for, handles a wide range—but knowing its limits is key.

So next time you’re planning a bore, maybe glance at the long-range forecast alongside your geology report. A little mindset shift can save you a ton of headache mid-job.

Got any weather-related HDD stories? The crazier the better—share them with me! We’re all in this dirt-filled, temperature-tossed world together.

Stay cool (or warm), and keep drilling smart.

Keep drilling smart,

By Frank

HDD Engineering Sales

RICHDRILL EQUIPMENT CO.,LTD

Share :