Hey there,

Remember that friend who’s always weirdly prepared? Rain jacket in a backpack, spare battery, an extra snack? Working with our drill rods in crazy temperatures kind of reminds me of that.

It’s not about being flashy; it’s about not letting the unexpected shut you down. Over the years, the real “aha!” moments haven’t come from lab reports, but from seeing crews just… keep going, when everything else suggests they should stop.

Let me share a couple of those moments with you.

That Inner Mongolia Cold That Felt Personal

So, like I mentioned last time, I was in Inner Mongolia in deep winter. We’re talking about a cold so intense it felt like a personal insult. I was honestly more worried about my own fingers than the equipment at first. The crew was running a pullback, and every time a rod came out, it was coated in a shell of frozen muck and groundwater that looked like a mud popsicle.

My brain was stuck on textbook worries: thermal contraction, impact toughness ratings. But the foreman, this guy named Li, just kept going. Between runs, he actually knocked one of our tool joints against a metal rack—not hard, just a tap. It gave off a clean, dull ping. He grinned and said, “Good steel doesn’t sing a high note in this cold. That’s when you get scared.”

That was my first real, visceral lesson. It’s not just about “not breaking.” It’s about the material staying predictably tough, not becoming glassy. Our heat treatment process is a long, slow dance of heating and cooling—it’s kind of boring to watch, honestly—but it forces the steel’s grain structure to get its act together.

The result? At -30°C, it’s still the same reliable, slightly stubborn partner you had at +20°C. It doesn’t get brittle and shockable. Li wasn’t looking for a hero; he was looking for that consistent, dull ping.

The Turpan Oven: Where Friction is the Real Enemy

Now, let’s flip to the opposite end of hell’s thermostat: a summer in Turpan. The air temperature was brutal, but any driller knows the real heat is born underground. It’s friction heat, the kind that builds up from constant grinding and doesn’t have anywhere to go.

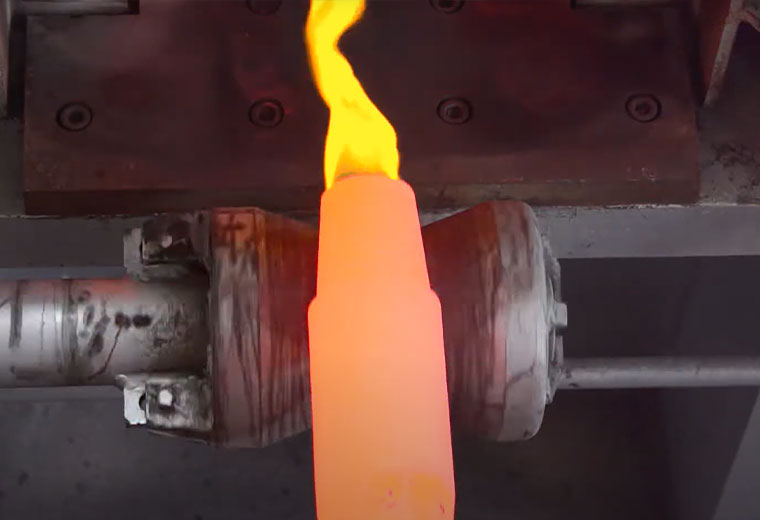

I saw a crew member spray water on a just-retrieved reamer. It sizzled like a steak on a skillet. That’s the environment. The danger here isn’t sudden fracture; it’s the slow creep of metal fatigue, the softening of threads, the warping that misaligns your whole string.

We once had a tool come back after a marathon bore in similar conditions. The coating was scuffed, sure, but it was all there—no peeling, no bubbling. The site boss pointed at it and said something that stuck with me: “A good finish shouldn’t just look pretty. It should work like the radiator on a vintage car.”

He was right. That matte, almost ceramic-like coating we use isn’t paint. It’s a permanent layer that does two huge things: it reflects a chunk of that radiant sun heat, and more importantly, it dissipates the internal friction heat faster. This keeps the core temperature of the tool more stable.

Stable heat means stable hardness, which means your threaded connections stay tight and true, not galled up from thermal expansion playing games with your tolerances.

The Real “Magic” is in the Boring Prep

Here’s my personal rant: there’s no magic. The “secret” is doing the boring, unsexy, meticulous work long before the tool ever sees a jobsite. It’s triple-checking the tempering charts. It’s being annoyingly picky about raw material batches. It’s testing coatings not just for corrosion, but for thermal conductivity.

A supplier once asked me, “Why do you spend so much on this final finish? It’s underground!” My answer was that picture of the sizzling reamer. The work happens underground, but the tool lives in the real world between runs—on the rack, in the sun, on the back of a truck. It has to survive that world, too.

So, What’s the Point of All This?

Look, I’m not telling you our hdd tools will drill by themselves while you sip coffee in the cab. What I’ve learned is that reliability in extremes isn’t a feature you can turn on. It’s baked into the DNA of the product through choices that might seem minor on a spec sheet.

The goal is to give you one less thing to worry about. Your mind should be on the bore path, on the slurry, on the site logistics—not on whether your last rod string is going to come out of the ground feeling a bit “off” because the weather turned.

When the forecast looks impossible, that’s when the prep work talks. And honestly, the best feedback I ever get is no feedback at all. It’s just a crew working through their plan, one rod at a time, as if the weather was just a mild inconvenience.

Stay safe, drill smart, and keep pushing forward.

Keep boring smart

By Frank

HDD Engineering Sales

RICHDRILL EQUIPMENT CO.,LTD

Share :